Original link below:

http://www.rexresearch.com/roschin/roschin.htm

|

Please Note: The publication found below is important in that scientists at

a major scientific institute, the Russian Academy of Science, have documented the

creation of free energy and have also documented striking anti-gravitic

effects that involve a prolonged and controllable loss of weight -- in

the same experiment.

Please Note: The publication found below is important in that scientists at

a major scientific institute, the Russian Academy of Science, have documented the

creation of free energy and have also documented striking anti-gravitic

effects that involve a prolonged and controllable loss of weight -- in

the same experiment.

The reported loss of weight involved hundreds of pounds in a system that was self-powering

while simultaneously generating seven kilowatts of power for external use.

That is to say that the system, once powered up, did not use any

external power to function, but actually produced power for external

use -- while displaying antigravitic effects by virtue of the fact

that the 350 kilogram system's weight fell by as much as 30%.

To the best of my knowledge, this is the only report of this

kind to ever appear - even though for decades there has been much

documentation that shows that individual inventors have been building

free energy devices since at least 1912. That would include the

free energy devices of Dr. Thomas Henry Moray. And Canadian

inventor John Hutchison demonstrated dramatic anti-gravitic effects as

early as the 1990s.

The report below was brought to my attention by a fellow

American scientist.

Dr. Koontz

Related article here

Related article here

|

V. ROSCHIN & S. GODIN

Magneto-Gravitational Converter

(Searl Effect Generator)

Experimental

Research of the Magnetic-Gravity Effects

by V. V. Roschin ( rochtchin@mail.ru ) &

S. M. Godin ( serjio@glasnet.ru )

Institute

for High Temperatures, Russian Academy of Science, Izhorskaya 13/19, Moscow

127412, Russia

[ This file is reproduced by courtesy of Alex Frolov: http://alexfrolov.narod.ru/ ]

Abstract ~

In the present paper the results of the experimental research of

Magnetic-Gravity Effects are presented. The abnormal magnetic and thermal

changes in the radius of 15 meters from the researched device were

measured as well. PACS: 41.20.-q; 44.60.+k; 76.50.+q

Introduction ~

There has been a great interest in examining nonlinear effects in the

system of rotating magnetic fields. Such effects have been observed in the

device called Searl's generator or SEG (SEG, Searl Effect Generator) [1-4]. An

SEG consists of a series of three rings and rollers that go around those

rings. All parts of SEG are based on the Law of the Squares. The rollers

revolve around the plates that form the rings, but they do not touch them.

There's a primary north and south pole on the rollers and a primary

north and south pole on the plates. Obviously you will have the north pole of

the roller attracted to the south pole of the plate. The plate and the rollers

have layered structure. The external layer - Titan, then Iron, Nylon and last

internal layer was made from Neodymium. John R.R. Searl has supposed that the

electrons are given off from the central element (which is neodymium), and

they travel out through other elements. If nylon had not been put there,

the SEG would act like a laser and one pulse would go out and it would stop,

build up, and another pulse would go out. But, with the nylon being, nylon

acts as a control gate, and that control gate gives you an even flow of

electrons throughout the SEG [4]. In [4] it was shown that in the process

of magnetization of the plate and rollers, the combination of constant

and variable magnetic fields for creating a special wave (sine wave) pattern

on a plate surface and rollers surface was used. The basic effects are the

rollers self-running around a ring plate and reduction of weight up to

occurrence of propulsion and flying up of all magnetic system. These effects

come about because of a special geometry of experimental setup. It was shown

that the work of the device in critical regime is accompanied by biological

and real physical phenomena. Unfortunately except for the listed references we

could not find other information where similar effects are be mentioned. In

this paper we present the experimental device the results we have obtained.

The Description of the Experimental Installation ~

The basic difficulty is in a choosing the materials and maintaining the

necessary pattern imprinting on the plate and rollers surfaces. To simplify

the technology we decided to use a one-ring design with one-ring plate

(stator) and one-ring of rollers (rotor). It is obvious, that it was necessary

to strengthen the rollers on a rotor by the bearings and balance the rollers

well. In the suggested design the air bearings were used which provided the

minimum losses due to friction. From the available description [1-4] it was

not clear how it is possible to make and magnetize the stator with a diameter

of about one meter. In order to make the stator from separate magnetized

segments executed on the basis of rare earth magnets with the residual

induction 1T; the segments were magnetized in a usual way by discharging

capacitor battery through the coil. Afterwards the segments were assembled and

glued together in a special iron armature, which reduced magnetic

energy. To manufacture the stator 110 KGs of rare earth magnets were used, and

to manufacture the rotor 115 KGs of that material was used. High-frequency

field under magnetization was not applied. It was decided to replace an

imprinting technology described in [1-4] with cross-magnetic inserts having a

flux vector directed at 90 degrees to a vector of basic magnetization of a

stator and rollers of a rotor. For these cross inserts the modified rare earth

magnets with a residual magnetization of 1,2 T and coercive force a little bit

greater than in a base material was used. In Figure 1 and Figure 2 the joint

arrangement of stator 1, elements of a rotor - rollers 2 and a way of their

mutual gearing by means of cross magnetic inserts 19, are shown. Between the

stator and roller surfaces the air gap d of 1 mm is left.

No layered structure was used except a continuous copper foil of 0.8 mm

thickness which wrapped up the stator and rollers. This foil has the direct

electrical contact to magnets of a stator and rollers. Distance between

inserts in the rollers is equal to distance between inserts on the stator.

Figure 1: Variant of One-Ring Converter ~

The ratio of parameters of the stator 1 and the rotor 2 in Figure 2 is

chosen so that the relation of stator diameter D and roller diameter d

is an integer equal to or greater then 12. Choosing such a ratio allows us to

achieve a magnetic spin wave resonant mode between elements of a working body

of the device.

Figure 2: Organization of Magnetic Gearing Stator & Rollers ~

The elements of magnetic system were assembled in a uniform design on the aluminum

platform. In Figure 3 the general view of the platform with one-ring

converter is displayed. This platform was supplied with springs, amortizators

and had a possibility of moving vertical on three supports. The value of

displacement was measured by the induction meter of displacement 14; thus the

change of the platform weight at once has been defined during the experiment

in real time. Gross weight of the platform with magnetic system in the initial

condition was 350 KGs.

Figure 3: General View of the Platform with One-Ring Converter ~

The stator 1 was mounted motionlessly, and the rollers 2 were assembled on

a mobile common separator 3, connected with the basic shaft 4 of the device.

Through this shaft the rotary moment was transferred. The basic shaft by the

means of friction muff 5 was connected to the electrodynamics generator 7 and

starting engine 6, which accelerated the converter up to a mode of

self-sustained rotation. Along a rotor the electromagnetic inductors 8 with

open cores 9 were located. The magnetic rollers 2 crossed the open cores of

inductors and closed the magnetic flux through electromagnetic inductors 8,

and induced emf in them, which acted directly on an active load 10 (a set of

incandescent lamps with total power 1 kW). The electromagnetic inductors 8

were equipped with an electrical drive 11 and had an opportunity to smoothly

move on supports 12. To study the influence of the external high voltage on

the characteristics of the converter the system of radial electrical

polarization was mounted. On periphery of the rotor ring electrodes 13

were set between the electromagnetic inductors 8 having with the rollers 2 air

gap of 10 mm. The electrodes are connected to a high-voltage source; the

positive potential was connected to the stator, and the negative to the

polarization electrodes. The voltage was adjusted in a range of 0-20 kV. In

experiments the constant value of 20 kV was used. In case of emergency

braking, friction disk from the ordinary car braking system was mounted on a

basic shaft of the rotor. The electrodynamics generator 7 was connected to

active load through a set of switches ensuring step connection of the load

from 1 kW to 10 kW. The converter under going testing had in its inner

structure the oil friction generator of thermal energy 15, intended for taping

a superfluous power (more than 10 kW) into the thermo-exchange contour. But

since the real output power of the converter in experiment has not exceeded 7

kW, the oil friction thermal generator was not used. The complete

stabilization of revolutions of the rotor was carried out by electromagnetic

inductors connected to an additional load, which was set of incandescent lamps

with total power 1 kW.

Experimental Results ~

The magnetic-gravity converter was built in a laboratory room on

three concrete supports at a ground level. The ceiling height the lab room

was 3 meters. Besides the presence of the iron-concrete ceiling, in

immediate proximity from the magnetic system there was a generator and

electric motor, which contained some tens KGs of iron and could potentially

deform the field's pattern. The device was started by the electric motor,

which accelerated the rotation of the rotor. The revolutions were smoothly

increased up to the moment the ammeter included in a circuit of the electric

motor started to show zero or lower value of a consumed current or even a

presence of the back current. The presence of the back current is detected at

approx. 550 rpm. The magnetic moving sensor 14 starts to detect the change in

weight of the whole installation at 200 rpm. Afterwards the electric motor is

completely disconnected by the electromagnetic muff and the ordinary

electrodynamics generator is connected to the basic shaft of the device

through the same muff. The rotor of the converter continues to self-accelerate

and with the approach to the critical mode of 550 rpm, the weight of the

device quickly changes. In addition to the change speed of rotation the weight

depend of the power, removed into active load, (the set of ten ordinary

electrical water heaters of 1 kW was used) and of the applied polarizing

voltage, as well. At the maximum output power equal to 6-7 kW the change of

weight G of the whole platform (total weight is about 350 KGs), reaches 35 %

of the weight in an initial condition G?. A load of more than 7 kW results in

a gradual decrease of revolutions and exit from the mode of self-generation

with the subsequent complete stop of the rotor. The weight of a platform can

be controlled by applying of a high voltage to cellular ring electrodes

located at a distance of 10 mm from external surfaces of the rollers. Under

the high 20 kV voltage (electrodes negative pole) the increase of taped power

in circuit of the basic generator more than 6 kW does not influence G while

the revolutions per min is not decreased to 400 rpm. "Tightening" of this

effect is observed as well as the effect of hysteresis on G (a kind of

"residual induction"). The experimental diagrams given on Fig.4 illustrate the

modes of the converter operations.

Figure 4: Modes of Operation of the Magnet-Gravity Converter ~

The effect of a local change of the platform weight is convertible relative

to the direction of rotor turning, and has the same hysteresis. At clockwise

rotation the critical mode comes in the area of 550 rpm and the propulsion

force against the direction of gravitation vector is created, by analogy, at

counter-clockwise rotation the critical mode comes the in area of 600 rpm and

the propulsion on the direction of gravitation vector is created. The

difference in approach to a critical mode of 50-60 rpm was observed. It is

necessary to mention that the most interesting region lies above the critical

area of 550 rpm, but due to of a number of circumstances the implementation of

such research was not possible. Other interesting effects include the work of

the converter in the dark room when corona discharges are observed around the

converter's rotor as a blue-pink glowing luminescence and a characteristic

ozone smell. The cloud of ionization covers the area of a stator and a

rotor and has accordingly toroidal form. On the background of luminescence

glowing on rollers' surfaces we distinguished wave picture. A number of more

vigorous strips of discharges around the rollers were observed. These

discharges were of the white - yellow colour is, but the characteristic for

the arc discharges sound was not audible. One more effect previously not

mentioned was observed i.e. the vertical magnetic "walls" around the

installation. We noticed and measured the abnormal permanent magnetic field

around the converter in the radius of 15 meters. The zones of an

increased intensity of a magnetic flux 0,05T located concentrically from the

centre of the installation were detected. The direction of magnetic

field vector in these walls coincided with the direction of rollers' field

vector. The structure of these zones reminded circles on water from the thrown

stone. Between these zones a portable magnetometer, which used the Hall's

sensor as a sensitive element, did not register abnormal magnetic fields. The

layers of an increased intensity are distributed practically without losses up

to a distance of about 15 meters from the centre of the converter and quickly

decrease at the border of this zone. The thickness of each layer is about 5 -

8 cm. The border of each layer has sharp shape, the distance between layers is

about 50 - 60 cm and it slightly accrues when moving from the centre of the

converter. The steady picture of this field was observed as well at a height

of 6 m above the installation (on the second floor above the lab.). Above the

second floor the measurements were not carried out. The abnormal fall of the

temperature in direct affinity from the converter was also found. While the

common temperature background in laboratory was + 22? (2?) the fall of

temperature equal to 6-8? was noticed. The same phenomenon was observed in

vertical magnetic walls as well as. The measurements of temperature inside the

magnetic walls were carried out by the ordinary alcohol thermometer with

inertia of indication about 1,5 min. In the magnetic walls the temperature

changes can be distinctly observed even by hand. The hand when placed into

this magnetic wall feels real cold at once. The similar picture was observed

at the height above installation, i.e. on the second floor of the laboratory

as well as despite the ferro-concrete blocking of ceiling.

Discussion ~

All the results we obtained are extremely unusual and require some

theoretical explanation. Unfortunately the interpretation of results within

the framework of the conventional physical theory cannot explain all the

observed phenomena and first of all the change of weight. The change of weight

is possible to interpret as a local change of gravity force or as an

occurrence of propulsion force by repelling from its own field.

Direct experiment, confirming a presence of draft force was not performed,

but in any case both interpretations of the weight change do not correspond to

the modern physical paradigm and demand reconsideration of the standard theory

of gravitation or criticism of the second law of Newton, both of which are

only possible if we take into consideration the now-advert physical media

ether as understood by Faraday-Maxwell-Mie. From the modern

physics position electrization and luminescence of the converter's magnetic

system in the near zone is not completely clear. The phenomenon of the

magnetic and thermal "walls" may be connected with Alphen's

magnetic-sound waves raised in near zone in magnetized plasma induced by a

variable magnetic field of a rotating rotor [5].

At the present time we can not give an exact description of the

interactions mechanism with environment and transformation of energy, but it

is completely obvious, that without the use of the concept of physical media

--- the ether in a sense of Faraday-Maxwell-Mie we are completely unable to

give physically substantial theory of these phenomena. In conclusion, we

emphasize that the issues of the biological influence effects and especially

of the variations of real time stream effects, which must be taking place in

an operative zone of the converter, were not considered at all. These

issues are extremely important and absolutely unexplored; though there are

some mentions of J.R.R.Searl about healing action of the SEG's radiation. Our

own experience allows to make only cautious assumption that the short-term

stay (dozen minutes) in a working zone of the converter with the fixed output

power of 6 kW remains for the people without observed consequences. The

present paper is only a beginning.

References ~

1. Herbert Schneider, Dr. J.B. Koeppl, Hans-Joachim Ehlers: "Begegnung mit

John R.R. Searl"; Raum und Zeit, #39 (1989), pp. 75-80.

2. S.

Gunnar Sandberg: "Was ist Dran am Searl-Effect; Raum und Zeit, #40

(1989), pp. 67-75.

3. Herbert Schneider & Harry Watt: "Dem

Searl-Effect auf der Spur"; Raum und Zeit, # 42 (1989), pp.75-81;

#43, pp.73-77.

4. John A. Thomas, Jr.: "Anti-Gravity: The Dream Made

Reality"; Extraordinary Science, VI (2) 1994.

5. L.D.Landau,

E.M.Lifshits: Electrodynamics of Continuous Media; Moscow, Nauka, 1982.

(in Russian)

Technical Physics Letters 26 (12): 1105-1107

(2000)

"An Experimental Investigation of the Physical Effects in

a Dynamic Magnetic System"

V.V. Roschin & S.M. Godin

Inst. of High Temperatures,

Russian Academy of Sciences, Moscow, Russia

Abstract ~

It is demonstrated that a magnetic system based on rare-earth magnets is

capable of converting various forms of the energy, provided that a certain

critical operating regime is set up. As the critical regime is attained, the

experimental setup becomes energetically fully autonomous. This is accompanied

by local variations in the total structure weight, a decrease in the

surrounding air temperature, and the formation of concentric "magnetic walls"

at a distance of up to 15 meters from the experimental setup.

Introduction ~

We have experimentally studied the physical effects in a system based on

rotating permanent magnets (1). Below we describe the technology of

manufacture, assembly, and the results of testing this experimental setup,

which is referred to as the converter.

Technological Description ~

The converter comprises an immobile stator and a rotor moving around the

stator and carrying fixed magnetic rollers. The magnetic system of the working

body of the converter has a diameter of about 1 meter. The stator and magnetic

rollers were manufactured from separate magnetized segments made of rare-earth

magnets (REMs) with a residual magnetization of 0.85 T, a coercive force of

[Hc] ~ 600 kA/m, and a specific magnetic energy of [W] ~ 150 K/m3. The

segments were magnetized by a conventional method based on a discharge of a

capacitor bank through an inductor coil. Then the magnetized segments were

assembled and glued together in a special mounting stage, which provided for

the necessary tolerance in positioning the segments and for the removal of

magnetic energy. Using this mounting stage, it was possible to glue the

elements into the common unit. The stable incorporated REMs with a total

weight of 110 kg and the rollers contained 115 kg of the same REM material.

The magnetic system elements were assembled into a single structure on a

special platform made of non-magnetic structural alloys. The platform

construction was provided with springs and shock absorbers and allowed the

converter setup to move in the vertical direction on three sides. The motion

was monitored by an inductive transducer. Which allowed changes ion the

platform weight to be determined in the course of the experiment. The total

weight of the platform with the magnetic system in the initial state was 350

kg.

Description of the Observed Effects ~

The converter was installed in a 2.5-meter high laboratory room using three

concrete supports on a ground level. In addition to the ordinary

steel-reinforced concrete ceiling blocks, the converter equipment featured a

usual electrodynamic generator and an electric motor, with a total iron weight

of several tens of kilograms (only these parts could, in principle, introduce

distortions into the electromagnetic field pattern observed).

The converter was set to operate by over-speeding the rotor with the aid of

the electric motor. The motor speed was gradually increased until the ammeter

connected in the motor circuit showed zero consumed current and the current

direction reversal. This state corresponded to a rotor speed of approximately

550 rpm, but the motion transducer began to indicate a change in the platform

weight already at 200 rpm. Then the electric motor was disconnected using an

electromagnetic overrunning clutch, and a usual electrodynamic generator was

connected instead to the main shaft of the converter via another

electromagnetic clutch. On attaining the critical regime (~550 rpm), the rotor

exhibited a sharp increase in the rotation speed; this was accompanied by a

slow-down in the rate of the current weight reduction. At this instant, the

first 1 kW load was connected to the system. Immediately upon this connection,

the rotation speed began to decrease, while the Delta G value kept increasing,

and so on as depicted in the figure.

A diagram illustrating various operation regimes of the

magnetogravitational converter showing (I) load power (kW) and system weight

variation; (II) 7-kW load (high voltage off); (III) 7-kW load (high voltage

on); (IV) supercritical regime; (V) subcritical regime (1, high voltage off;

2, high voltage on).

The system weight variation depend both on the power consumed by the active

load (the load consisted of 10 ordinary 1-kW heating elements) and on the

polarization voltage applied. For a maximum consumed power (7 kW), a change in

the total platform weight reached 35% of the initial value in the immobile

state (350 kg), which corresponded to 50% of the pure weight of the working

body of the converter. An increase in the load power above 7 kW led to a

gradual decrease in the rotor speed and, eventually, to the system going out

of the self-generation regime and the rotor speed decreasing until the full

stop. The platform weight could be controlled by applying a high-voltage

signal to the cellular ring electrodes situated 10 mm above the external

roller surface. Upon applying a 20 kV signal (negative polarity on the

electrodes), an increase in the load power consumption above 6 kW did not

affect the Delta G value even when the rotor speed decreased down to 400 rpm.

This was equivalent to "prolongation" of the effect and was accompanied by

phenomena of the remnant induction" type with respect to Delta G. The

converter operation in various experimental regimes is illustrated in the

figure.

The effect of the system weight variation is reversible with respect to the

direction of rotor motion and exhibits certain hysteresis. For the clockwise

rotation, the critical regime is observed in the region of 550 rpm and is

accompanied by development of the force acting against the gravity vector. For

the counter-clockwise rotation, the onset of the critical regime is observed

at approximately 600 rpm and the extra force coincides in direction with the

gravity vector. The onset of the critical regime exhibited a scatter within

50-60 rpm. It should be noted that, probably, some other critical resonance

regimes may exist, which correspond to higher rotor speeds and markedly

greater useful load levels. Proceeding from the general theoretical

consideration, the output mechanical energy must nonlinearly depend on the

internal parameters of the converter magnetic system and the rotor speed, so

that the observed effects are likely to be far from optimum. Establishing of

the maximum output power maximum weight variation, and the converter energy

resource is of considerable theoretical and practical interest.

Besides the phenomena described above, a number of other interesting

effects were observed in the system studied. In particular, the converter

operation in the dark is accompanied by a corona discharge with a pink-blue

light emission and by the production of ozone. The ionization cloud is formed

around the stator and rotor, acquiring a toroidal shape. The general corona

discharge background is superimposed with a wavy pattern corresponding to the

surface of the rollers: the zones of increased emission intensity are

distributed along the roller height in a manner similar to that observed for

the high-voltage microwave induction energy storage in the pre-breakdown

state. These zones appeared yellowish-white, but the emission was not

accompanied by sounds characteristic of the arc discharge. Nor did we observe

any visible erosive damage on the stator and rotor surfaces.

One more effect, which was never reported previously, is the appearance of

vertical "magnetic walls" surrounding the setup. We have detected and measured

an anomalous constant magnetic field around the converter. The measurements

revealed zones of increased magnetic strength on the order of 0.05 T arranged

coaxially relative to the system center. The direction of the magnetic field

vector on the "walls" coincides with that in the rollers. The structure of

these magnetic zones resembles the pattern of circular waves on the water

surface. No anomalous field is detected by a mobile magnetometer, employing

the Hall effect transducer, in the area between zones. The layers of increased

magnetic field strength are propagating with virtually no attenuation to a

distance of 15 meters from the converter center and then rapidly decayed at

the boundary of this 15-meter area. Each layer zone is 5-8 cm thick and

exhibits sharp boundaries. The layers are spaced by 50-60 cm, the spacing

slightly increasing with the distance from the converter center. A stable

pattern was also observed at a height of 5 meters above the setup (the

measurements were conducted in a 2nd floor room above the laboratory; no tests

were conducted on a still higher level).

Another interesting phenomenon consists in an anomalous temperature drop in

the immediate vicinity of the converter. At a general room temperature level

in the laboratory (+22 +-2 C), the temperature at the converter surface was

6-8 C lower. Similar temperature variations were detected in the vertical

magnetic "walls". The temperature changes in the walls were detected by an

ordinary alcohol thermometer with a reading set time of 1.5 minutes. The

temperature variations in the magnetic "walls" can even be sensed by the human

body: a hand placed inside the "wall" immediately feels cold. The same pattern

was observed at a height of 5 meters above the setup in a 2nd floor room above

the laboratory (despite the steel-reinforced concrete blocks separating the

rooms).

Discussion of Results ~

All the experimental results described above are very unusual and need some

theoretical rationalization. Unfortunately, attempts at interpreting the

obtained results within the framework of the existing physical theories showed

that no one of these models can explain the whole set of experimental data.

Recently, Dyatlov (2) attempted to combine the concepts of electricity and

gravity by introducing the so-called electro-navigation and magnetic-spin

coefficients into the Heaviside gravity equations and the Maxwell field

equations. This provides for a relationship between the gravitational and

electrical components, as well as between the magnetic and rotational

components in a given medium. The assumptions are built around a special model

of inhomogeneous physical vacuum, called the vacuum domain model (2). It is

suggested that the extra relationships are absent outside the vacuum domain.

Although it is difficult to imagine a long-living vacuum domain, the proposed

model provides for a satisfactory explanation (at least on a qualitative

phenomenological level) for the appearance of emission, the system weight

variations, and the conversion of energy taken from the surrounding medium

into the rotational mechanical moment of the rollers. Unfortunately, the

theory cannot provide a physical pattern of the observed phenomena.

Conclusion ~

At present, the work on a developed variant of the converter are in

progress at the Glushko "NPE Energomash" company (Moscow). This setup would

allow a deeper insight into the physics of observed phenomena. Another aim is

the creation of commercial samples for various practical applications.

References ~

(1) Thomas, J.A.: Anti-Gravity: The Dream Made Reality ~ The Story of

John R.R. Searl; Direct International Science Consortium, London,

1994), Vol. 1, Issue 2.

(2) Dyatlov, V.L.: Polarization Model

Heterogenous Physical Vacuum (Inst. Mat., Novosibirsk, 1998); Translated

by P. Pozdeev.

M. Pitkanen: About Strange Effects Related to Rotating Magnetic

Systems ~ An explanation of the Roschin-Godin experiment in

terms of Topological Geometro-Dynamics (TGD). [PDF: Requires Adobe Acrobat]

Roschin/Godin: Russian Patent #

2,155,435

US Patent # 6,822,361

US Cl. 310/178 ~ November 23, 2004

Orbiting Multi-Rotor Homopolar System

Roschin; Vladimir Vitalievich (Moscow, RU); Godin; Sergi

Mikhailovich (Moscow, RU)

Abstract -- An orbiting multi-rotor homopolar machine employs

axially parallel, cylindrical, electrically conductive magnets arranged

circumferentially around vertical axis of central stator ring, intimately

contacting and engaging non-slip rolling between rotor magnets and stator. A

bearing rotatably secures each end of each magnet to a corresponding

electrically conductive circular endplate, each slightly wider than the

stator. An electrically conductive axle located in the center of the stator

rigidly attaches to one of the top circular endplate, and an electrically

insulating bearing means attaches the center of bottom circular endplate to a

coaxial inner cylinder, located between the axle and the stator.

Assignee: Energy & Propulsion Systems LLC (Valencia, CA)

References Cited

U.S. Patent Documents:

406,068 ~

Jul., 1889 ~ Tesla ~ 310/178

645,943 ~ Mar., 1900 ~ Dalen, et al. ~

310/178

3,185,877 ~ May., 1965 ~ Sears ~ 310/178

3,465,187 ~ Sep.,

1969 ~ Breaux ~ 310/178

5,241,232 ~ Aug., 1993 ~ Reed ~ 310/178

5,278,470 ~ Jan., 1994 ~ Neag ~ 310/178

5,977,684 ~ Nov., 1999 ~ Lin ~

310/178

6,051,905 ~ Apr., 2000 ~ Clark ~ 310/178

Foreign Patent

Documents:

2,094,066 ~ Sep., 1982 ~ GB

2000-324,786 ~ Nov., 2000 ~

JP

2001-286,117 ~ Oct., 2001 ~ JP

2003-47,226 ~ Feb., 2004 ~ JP

Primary Examiner: Mullins; Burton ~ Attorney, Agent or Firm:

Our Pal LLC

Description ~

FIELD OF THE INVENTION

This invention relates generally to the field of direct current electrical

motors and generators that operate without the need for commutation and/or

rectification, and more particularly to multi-rotor homopolar machines which

derive their emf (electromotive force) from co-rotational magnets and metallic

disk embodiment.

BACKGROUND

Back in 1831, Michael Faraday discovered that a cylindrical magnet

suspended by a string and touching a mercury bath at the bottom could generate

electricity while spinning along its axis if a second electrical contact was

made at the periphery of the midpoint of the magnet. His experiment was a

one-piece homopolar machine since the magnet and conductor were joined

together. Such Faraday generators have also been called acyclic, unipolar or

homopolar generators because no commutation or alternating of the magnetic

poles is necessary for this machine in order to generate electricity.

The type of electrical output is most often direct current (DC) unless

specific means are designed to provide an interruption of radial conduction

and thus simulate alternating current (AC). Historically, DC was championed by

Thomas Edison during the early part of the 20th century while at the same time

AC was championed by Nikola Tesla and George Westinghouse. In the future, DC

will be coming back into style with the emergence of ambient temperature

superconductive cables. Therefore, highly efficient homopolar generators will

be in demand to meet the future market demand for DC electricity.

Homopolar generators usually have a single disk or drum rotating in a

stationary magnetic field with sliding contacts. The sliding contacts often

present high resistance however. The construction and operation of homopolar

machines for electric propulsion of marine vessels or railguns for example is

already well known. Such machines include motors and generators wherein

electrical current flows through a conductor situated in a magnetic field

during rotation of the machine rotor.

In the case of a homopolar motor, the current will develop a J.times.B

force perpendicular to the direction of its flow through the conductor and

that of the magnetic field. In the case of a homopolar generator, a voltage

dependent on the rotational speed, magnetic field, and radius, is induced in a

conductor moving within the magnetic field. When current is drawn from the

homopolar generator, it also develops a J.times.B force for the same reason as

with the motor but is referred to as back torque or armature reaction. General

reference information including basic principles used to reduce back torque

can be found in The Homopolar Handbook by Thomas Valone (ISBN 0-9641070-1-5).

The prior art rarely includes a one-piece homopolar machines that rotate

the magnet with the disk. Even more unknown is the concept of rolling

contacts. Eliminating sliding contacts is shown in the "Planetary Homopolar

Generator," IBM Technical Disklosure Bulletin, Vol. 17, No. 6, p. 1786-87,

November, 1974, H. D. Varadarajan.

Using a conducting belt or rolling contacts to gather current from a

magnetic field flux cutting rotor, there is an annular magnetic field through

which the rotor executes a planetary motion.

The large stresses resulting from the centrifugal force of the massive,

unbalanced planetary rotor is a distinct disadvantage, prohibiting high speed

operation. Thus, only a low rate of rotation is possible with the IBM design.

The "Direct Current Homopolar Machine" U.S. Pat. No. 5,587,618 to Hathaway

demonstrates an analogous concept of relative motion between conductive

orbiting shaft and a stationary disk-shaped magnetized armature.

However, the design is a bit cumbersome to be practical. Science

Applications International Corporation claims a conductive belt, dual disk

"Homopolar Motor-Generator" in U.S. Pat. No. 5,241,232 to Reed that apparently

reinvents the "Dynamo Electric Machine" of U.S. Pat. No. 406,968 patented by

none other than Nikola Tesla in 1889 that also has two unipolar magnetized

rotors connected by a conductive belt. The belted dual unipolar machines solve

one of the problems that plague the field by offering two sliding contacts at

the low speed surface on the axle. However, the present invention requires

only one sliding contact on the axle. These conductive belt machines also

demonstrate, in principle, the concept of a multi-rotor, planetary design, by

the process of coordinate transformation, since relative motion is the key to

the operation of a homopolar generator. The concept of rolling contact is

demonstrated with the Dalen "Dynamo Electric Machine" U.S. Pat. No. 645,943,

where two disks are turning in opposite directions while in contact with each

other at their periphery. However, the axle of each disk must remain fixed in

place whereas each axle is in orbiting motion in the present invention.

Homopolar machines can reversibly function as motors as well, such as

flywheels, and used as energy storage devices. First used in transportation

applications in the 1950's, flywheel powered buses were designed to have the

flywheel accelerated at every stop. Composite rotors currently have been

developed which can spin at very high revolutions (100,000 revolutions per

second); and the speed is limited by the tensile strength of the rim of the

rotor. By using a multi-rotor design, the centrifugal forces of a large disk

can be greatly reduced and still maintain high-energy storage or production.

By using magnetic bearings, the friction on the axis of the rotor can be

reduced sufficiently so that such rotors can maintain most of the energy for

several days.

The IBM Varadarajan planetary rotor is unbalanced and has a low rate of

magnetic flux cutting due to its annular magnetic field design. The Hathaway

direct current machine has a lot of unbalanced conductive material orbiting

the central magnetized disk which limits the rotational speed.

The conductive belt designs can be subject to oxidation and slippage, even

requiring a toothed timing belt on each axle as well. With most disk models of

homopolar generators, as opposed to drum designs, sliding contacts are the

single most important contribution of resistance inhibiting the power output

of the machine. Internal resistance is the only limit to the output capability

of a homopolar generator and it is important to reduce all sources of internal

resistance to obtain maximum power output for a given input torque. Rather

than use high resistance carbon brushes, medium resistance silver-graphite

brushes or dangerous conductive liquids such as mercury, low temperature

solder, or sodium-potassium, there is a need to eliminate frictional sliding

contact at the high speed periphery of the magnetized rotor completely.

Furthermore, rather than maintaining two sliding contacts which contribute

friction and resistance, even in the rolling and belted designs, there is a

need to cut the number in half to only one high current sliding contact. The

present invention satisfies both of these needs.

SUMMARY

The present invention derives direct current electricity by co-rotating a

plurality of magnets and a metallic disk. It comprises an improved homopolar

machine with dynamically balancing, axially parallel, cylindrical,

electrically conductive magnets arranged circumferentially around the vertical

axis of central stator ring. Such a design can be referred to as distributed

generation since each magnet rotor generates only a fraction of the current

that is transmitted through the machine. Thus, the conductive bearings

contacting the center of each end of the magnet rotors may carry only one

tenth or less of the total current.

The multi-rotor orbiting homopolar also does not include sliding contacts

at each magnetized rotor rim but instead utilizes a suitable rolling means

attached separately to magnets and also to the stator ring for intimately

contacting and engaging non-slip rolling between magnets and stator as they

orbit around the stator. The magnetized rotors maintain rotational synchronism

and equal relative position to each other with a bearing means rotatably

securing the top and bottom end of each magnet to a corresponding electrically

conductive circular endplate.

The electrical energy is extracted, or input if used as a motor, through

contacts on the conductive stator and at the machine's electrically conductive

axle located in the center of the machine while rigidly attached to the top

circular endplate that rotates with all of the individually magnetized rotors.

The only single, high current, moving contact that is required is an

electrically conductive thrust bearing that supports the central axle. An

insulating thrust bearing meanwhile separates the axle from the center of

bottom circular endplate. The stator, which is of course stationary,

accomplishes the second contact means through a standard electrical connection

with no need for any relative motion sliding contact. The stator may be

optionally magnetized in the opposite direction to the magnetized rotors in

order to increase the coercive force or magnetic flux density.

The drawings constitute a part of this specification and include exemplary

embodiments to the invention, which may be embodied in various forms. It is to

be understood that in some instances various aspects of the invention may be

shown exaggerated or enlarged to facilitate an understanding of the invention.

The Problem ~

The problem this invention solves is that it generates high power direct

current electricity without the need for commutation and rectification,

otherwise the internal resistance losses are high.

The problems with prior art devices, processes and systems can be

categorized as follows.

1. Require commutation or rectification to generate direct current

electricity.

2. Rely on more than one current brush which often have high speed contact.

3. Do not distribute magnetic field power generation by multi-rotor

orbiting magnets in homopolar machines or systems.

4. Internal resistance losses are usually high.

5. Neither efficient nor cost effective.

6. Neither simple nor practical for most applications.

Prior Art ~

A preliminary limited prior art search was not commissioned but the

inventor is intimately familiar with the prior art. Following are typical

examples of the prior art arranged in reverse chronological order for ready

reference of the reader.

11) Non-Provisional Utility U.S. Pat. No. 6,051,905 issued to Richard Clark

on Apr. 18, 2000 for "Homopolar Generator"

10) Non-Provisional Utility U.S. Pat. No. 5,977,684 presented to Ted Lin on

Nov. 2, 1999 for "Rotating Machine Configurable as True DC Generator or Motor"

09) Non-Provisional Utility U.S. Pat. No. 5,864,198 earned by Joseph

Pinkerton on Jan. 26, 1999 for "Brushless Generator"

08) Non-Provisional Utility U.S. Pat. No. 5,587,618 issued to George

Hathaway on Dec. 24, 1996 for "Direct Current Homopolar Machine"

07) Non-Provisional Utility U.S. Pat. No. 5,278,470 graced upon Zacharias

Neag on Jan. 11, 1994 for "Homopolar Machine which acts as a Direct Current

(DC) High Voltage Generator or Motor"

06) Non-Provisional Utility U.S. Pat. No. 5,241,232 honorably given to Jay

Reed on Aug. 31, 1993 for "Homopolar Motor-Generator"

05) Non-Provisional Utility U.S. Pat. No. 5,011,821 published in the name

of Charley McCullough on Apr. 30, 1991 for "Method and Apparatus for

Generating Electricity"

04) Non-Provisional Utility U.S. Pat. No. 3,465,187 issued to Onezime

Breaux on Sep. 2, 1969 for "Homopolar Generator Having Parallel Positioned

Faraday Disk Structures"

03) Non-Provisional Utility U.S. Pat. No. 3,185,877 presented to Anthony

Sears on May 25, 1965 for "Direct Current Homopolar Generator"

02) Non-Provisional Utility U.S. Pat. No. 645,943 graced upon inventor

Gustaf Dalen on Mar. 27, 1900 for "Dynamo Electric Machine"

01) Non-Provisional Utility U.S. Pat. No. 406,968 bestowed upon none other

than Nikola Tesla himself in 1889 for "Dynamo Electric Machine"

None of the prior art devices known to the applicant or his attorney

disclose the EXACT embodiment of this inventor that constitutes a simple,

elegant and affordable system for an orbiting Multi-Rotor Homopolar direct

current electricity generation

Objectives ~

Unfortunately none of the prior art devices singly or even in combination

provide for all of the objectives as established by the inventor for this

system as enumerated below.

1. It is an objective of this invention to provide devices, method and

system for generation of high power direct current electricity without

commutation and rectification.

2. The primary objective of the invention is orbiting multi-rotor

cylindrical magnets in rolling contact that eliminates friction while

generating DC electricity.

3. Another objective of the invention is to provide high efficiency, low

noise and low resistance in a high current generator.

4. Another objective of the invention is that it uses readily available

materials in a dynamically balanced arrangement.

5. Another objective of the invention is safety through reduced internal

stress than comparable homopolar machines with a single rotor.

6. Another objective of the invention is that it provides distributed

generation around an air core.

7. Another objective of this invention is to provide an easy, quick, simple

practical way to generate more efficient and cost effective direct current

electricity.

8. Another objective of this invention is that it promote and encourage

other inventors to do additional research in homopolar machines generally but

co-rotational magnets and disk embodiments in particular.

9. Another objective of this invention is to provide a system that is

integrated and flexible.

10. Another objective of this invention is to provide a system that is

easily useable and requires little if any training for manufacturing and use.

11. Another objective of this invention is that it meet all federal, state,

local and other private standards guidelines, regulations and recommendations

with respect to safety, environment, and energy consumption.

12. Another objective of this invention is that it can be made from modular

standard materials and components that are also easily maintainable.

Other objectives advantages and features of this invention reside in its

simplicity, elegance of design, ease of manufacture, service and use and even

aesthetics as will become apparent from the following brief description of the

drawings and the detailed description of the best mode preferred embodiments

taken in connection with the accompanying drawings.

BRIEF DESCRIPTION OF THE DRAWINGS

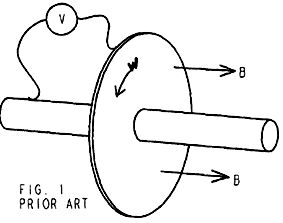

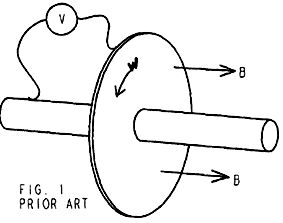

FIG. 1 is a prior art diagram of a typical homopolar generator.

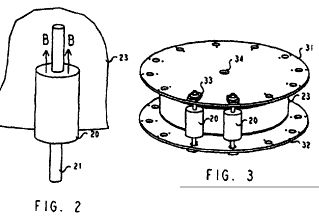

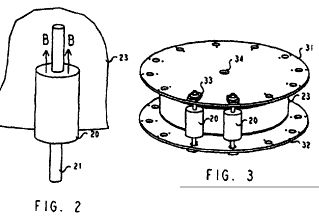

FIG. 2 is a perspective, cutaway view of the magnetized rotor and

stator.

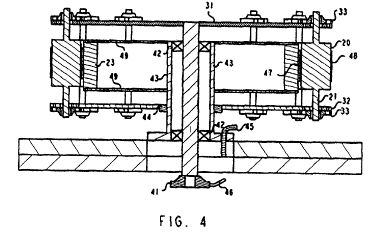

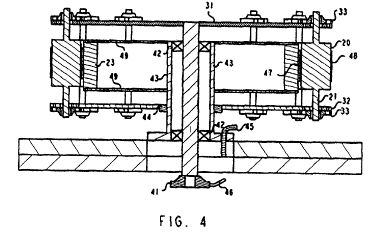

FIG. 3 is an elevational view of the complete orbiting multi-rotor

machine.

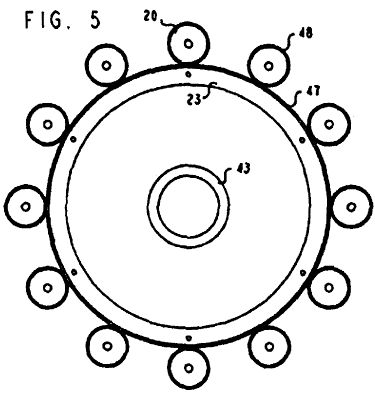

FIG. 4 is a cross sectional view of the invention.

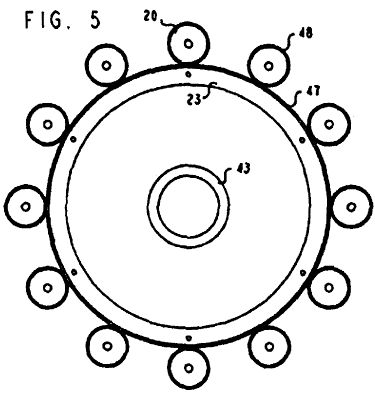

FIG. 5 is a plan view from the top of the invention.

DETAILED DESCRIPTION OF THE BEST MODE PREFERRED EMBODIMENT

As shown in the drawings wherein like numerals represent like parts

throughout the several views, there is generally disclosed in FIG. 1 is a

state of the prior art.

Detailed descriptions of the preferred embodiment are provided herein. It

is to be understood, however, that the present invention may be embodied in

various forms. Therefore, specific details disclosed herein are not to be

interpreted as limiting, but rather as a basis for the claims and as a

representative basis for teaching one skilled in the art to employ the present

invention in virtually any appropriately detailed system, structure or manner.

Turning first to FIG. 2 there is shown a perspective cutaway view of a

portion of one embodiment of the present invention showing one of a multitude

of rotors that are axially magnetized (B). This multitude mounted in parallel

comprise the multi-rotor homopolar machine in close contact with a ring shaped

stator that may be optionally magnetized in the direction opposite to the

magnetic fields of the rotors.

Each rotor 20 has its own axle 21 which is circumferentially mounted

vertically, arranged and dynamically balanced around a central vertical axis,

on an electrically conductive but low permeability axle rod 21 made of copper,

brass or bronze, that may penetrate the center of the entire magnetized rotor

and rotatably attach to top and bottom bearing 33 on circular endplates 31, 32

shown in FIG. 3. In operation, the rotors orbit around the circular stator

ring, which may or may not also be magnetized.

The invention is more completely shown in the elevational view of FIG. 3

with several rotors 20 rotatably attached to the top circular endplate 31 and

bottom circular endplate 32 by electrically conductive bearings 33. The top

endplate 31 is rigidly attached to the central axle 34 supporting the orbiting

multi-rotor homopolar generator assembly. The hollow circular design of the

stationary ring stator 23 is also visible in FIG. 3, which can be optionally

magnetized to increase performance output.

The bottom circular endplate 32 has a large hole in the center, more

completely seen in FIG. 4, that allows inner attachment to insulating bearing

44 which optimally can be a non-contacting, low friction magnetic bearing

since the weight of the rotor assembly is carried by the electrically

conductive thrust bearing 41. The bottom endplate 32 is thus isolated

electrically from the stationary Inner cylinder 43 that is the inner core of

the stator. Inner circular assembly plates 49 of equal size and shape, that

preferably are electrically conductive, rigidly attach the inner cylinder 43

to the stator ring 23. In accordance with the present invention, FIG. 4 shows

the side cross sectional view edge on with a cutaway so that the central axle

34 and hollow inner cylinder design 43 is visible.

The insulating bearings 42 separate the central axle 34 from the inner

cylinder 43. Both bearings 42 and 44 electrically maintain the separation of

polarity of the electromotive force (emf) voltage of each rotor. The positive

or negative polarity of the conductors depends of course on the rotation

direction of the rotor magnets. One conductor 45 is electrically emerging from

the stator assembly and ultimately emanates from the outer edge of each rotor

20 with the homopolar effect conducting the generated electricity through the

rolling means 47 and 48. The opposite polarity conductor 46 is electrically

emanating from the center axle 21 of each rotor 20 is connected to the

electrically conductive thrust bearing 41.

In accordance with an important function of the present invention, there is

shown in FIG. 4 one embodiment of an intimately contacting and engaging

nonslip rolling means 47 and 48. As is well-known in the industry where good

traction with a high coefficient of friction (1.6 or better) but sufficiently

low electrical resistance is desired between two surfaces, an adherent coating

of copper can be used on both facing surfaces of the stator 23 and rotor 20.

For the copper coating, electro-deposition can be used or flame spraying of

copper on the rotor and stator outer surfaces.

Another embodiment of rolling means 47 and 48 utilizes a geared

electromechanical rotary joint developed by NASA Goddard Space Center (NASA

Tech Briefs, December, 1994) which offers the advantage of a springy, low

noise planetary gear contacting a stator ring gear. It was designed by NASA to

overcome the disadvantages of sliding contacts and to ensure high traction

desired for rolling electrical contacts.

The springy gears are made from beryllium copper which is a self-cleaning

material with, in one embodiment, an average diameter of 6.35 mm with any

reasonable number of teeth. Another concept to creating a rolling contact

utilizes a magnetic sprocket design with small rare earth (samarium cobalt for

example) magnets embedded perpendicularly in the surfaces of the stator ring

and rotor magnets. The magnetic sprocket thus utilizes equally spaced magnets

mounted normal to the axes of the stator and rotor.

To demonstrate an important feature of the invention, there is shown in

FIG. 5 a plan view from the top of the balanced distribution of the rotors 20

around the stator assembly 43 with the outer stator ring 23 that are equally

spaced and preferably dynamically balanced so the centrifugal forces are equal

and opposite.

Theory of Operation ~

The main principle of operation is based on the fact that rotating

cylindrical magnets creates a homopolar emf generation from Faraday's Law and

the Lorentz Force. Physically, a rotating, non-inertial reference frame

configuration can only be analyzed correctly with Einstein's general theory of

relativity, utilizing a Thirring metric.

Particularly, where rotating cylindrical magnets and disk are synchronized

and made co-rotational, such a co-rotational configuration makes the generator

one piece like the earth's magnetic field itself. As the inventors explored

this correspondence more closely, it was learned that the earth's molten,

electrically conductive iron core also includes not one but several vortices

in a coaxial circular arrangement. The inventors stumbled upon this concept

while investigating the field rotation paradox and found that an orbiting,

multi-rotor homopolar generator assembly would be analogous to the earth's

electrically conductive, multi-vortex, magnetic, molten iron core.

The field rotation paradox can be easily resolved by an amateur DIY (Do It

Yourself ) scientist by comparing the interception of a linear magnetic field

vs. a rotating magnetic field. In the former configuration the meter gives the

same reading whether the magnet is moved with respect to a pickup coil of wire

or vice versa but in the latter configuration the meter reading is seen only

when the disk is moved with respect to rotary magnetic field of cylindrical

magnet but not when the magnet is moved with respect to the disk. The former

is consistent with special relativity while the latter is relying on general

relativity. Both are loosely termed "relativistic."

Assembly and Use ~

The manufacturing, assembly and use of this invention is very simple even

intuitive. The system of this invention can be readily assembled from the

teaching provided in this disclosure by state of the art techniques and

materials by a person of average skill in the art.

The applicant has described the essence of this invention. While this

invention has been described with reference to an illustrative embodiment,

this description is not intended to be construed in a limiting sense. Various

modifications and combinations of the illustrative embodiments as well as

other embodiments of the invention will be apparent to a person of average

skill in the art upon reference to this description.

Variations ~

Due to the simplicity and elegance of the design of this invention

designing around it is very difficult if not impossible. Nonetheless many

changes may be made to this design without deviating from the spirit of this

invention. Examples of such contemplated variations include the following:

1. The shape and size, colors etc of the device or the packaging thereof

may be modified.

2. Additional complimentary and complementary functions and features may be

added.

3. The system of this invention may be adapted for other related uses.

4. Instead of cylindrical magnets, other types of magnets and mode of

mounting on the disk may be employed to create the orbiting, rotational

magnetic field.

5. The invention may be scaled up and down by several orders of magnitude

7. An experimental science toy version may be developed for education and

entertainment of little young scientists of the future.

8. Homopolar generator may be employed in reverse as a motor to convert

electrical energy into mechanical energy.

9. A homopolar servo motor version may be crafted based on this

co-rotational magnet and disk concept.

10. Permanent cylindrical magnets may be replaced by equivalent

configuration of electromagnets.

11. A portion of the emf generated may be fed back to cylindrical

electromagnets to explore the possibility of a self-excited generator without

violating any laws of nature.

Other changes such as aesthetics and substitution of newer materials as

they become available, which substantially perform the same function in

substantially the same manner with substantially the same result without

deviating from the spirit of the invention may be made.

Following is a listing of the components used in the best mode preferred

embodiment and the alternate embodiments for use with OEM as well as retrofit

markets. For the ready reference of the reader the reference numerals have

been arranged in ascending numerical order.

10 = Prior art generally

20 = Rotor(s)

21 = Axle, rod

23 = Stationary Ring Stator (Optionally Magnetized)

31 = Top circular end plate

32 = Bottom circular end plate

33 = Bearing

34 = Central Axle

41 = Electrically Conductive Thrust Bearing

42 = Insulating Bearing

43 = Stationary Hollow Inner Cylinder

44 = Insulating Bearing

45 = Opposite Polarity Conductor

46 = Opposite Polarity Conductor

47 = Non-Slip Rolling Means

48 = Non-Slip Rolling Means

49 = Inner Circular Assembly Plates

Definitions and Acronyms

A great care has been taken to use words with their conventional dictionary

definitions. Following definitions are included here for clarification.

3D = Three Dimensional

Acyclic = Non-cyclic, non rotational or linear

DC = Direct Current as contrasted from alternating current electricity

DIY = Do It Yourself

DYNAMO = A device for converting mechanical energy into electrical energy

(& Vice versa)

EMF = Electromagnetic Force

Homopolar = Same as unipolar

Integrated = Combination of two entities to act like one

Interface = Junction between two dissimilar entities

N = Magnetic North (Permanent or electro-magnet)

N-Machine = One Piece Faraday generator

OEM = Original Equipment Manufacturer

S = Magnetic South (Permanent or electro-magnet)

Unipolar = Same as homopolar

Note: It should be noted that the prior art uses unipolar, homopolar,

acyclic and Faraday Disk Dynamo interchangeably.

While this invention has been described with reference to illustrative

embodiments, this description is not intended to be construed in a limiting

sense. Various modifications and combinations of the illustrative embodiments

as well as other embodiments of the invention will be apparent to a person of

average skill in the art upon reference to this description. It is therefore

contemplated that the appended claim(s) cover any such modifications,

embodiments as fall within the true scope of this invention as defined by the

appended claims.

Claims ~

What is claimed is:

1. An orbiting multi-rotor homopolar machine comprising:

a plurality of axially parallel, equally spaced, cylindrical, magnet rotors

arranged circumferentially around the periphery of a central stator ring whose

axis is parallel to each magnet rotor axis;

rolling means attached separately to the magnet rotors and to the stator

ring for intimately contacting and enabling high friction non-slip rolling

between magnet rotors and stator ring;

means for starting and sustaining orbiting rolling of the magnet rotors

around stator ring as required;

bearing means rotatably securing the top and bottom ends of each magnet

rotor to a corresponding circular endplate;

axle means located in the center of the stator ring rigidly attached to the

top circular endplate;

electrically insulating bearing means rotatably securing the center of the

bottom circular endplate to a coaxial inner cylinder located between the axle

and stator ring; and

circular assembly means for rigidly attaching the inner cylinder to the

stator ring.

2. The homopolar machine of claim 1 wherein the inner cylinder, circular

assembly means, magnet rotors, axle means, circular endplate, and stator ring

are made at least partially from electrically conductive material.

3. The homopolar machine of claim 1 wherein the rolling means comprises an

electrically conductive geared electromechanical rotary joint.

4. The homopolar machine of claim 1 wherein the rolling means comprises an

electrically conductive copper coating on the stator ring and magnet rotors.

5. The homopolar machine of claim 1 wherein the stator ring comprises

electrically conductive magnetic material.

6. A method for starting and sustaining the orbiting of rolling cylindrical

magnets arranged parallel to and circumferentially around the vertical axis of

a central stator ring, while intimately contacting and engaging non-slip

rolling means between rotor magnets and the stator ring, rotatably securing

the top and bottom ends of each rotor magnet by means of a bearing to a

corresponding circular endplate, rigidly attaching to the top circular

endplate a vertical axle coaxial with and in the stator ring, securing the

center of the bottom circular endplate to a coaxial inner cylinder located

between the axle and the stator ring by means of an electrically insulating

bearing, and rigidly attaching the inner cylinder to the stator ring by means

of a circular assembly.

7. An orbiting multi-rotor homopolar machine comprising:

a plurality of axially parallel, equally spaced, cylindrical, magnet rotors

arranged circumferentially around the periphery of a central stator ring whose

axis is parallel to each magnet rotor axis;

rolling means attached separately to the magnet rotors and to the stator

ring for intimately contacting and enabling high friction non-slip rolling

between the magnet rotors and stator ring;

means for starting and sustaining orbiting rolling of the magnet rotors

around the stator ring as required;

bearing means rotatably securing the top and bottom ends of each magnet

rotor to a corresponding circular endplate;

axle means located in the center of the stator ring rigidly attached to the

top circular endplate;

electrically insulating bearing means rotatably securing the center of the

bottom circular endplate to a coaxial inner cylinder located between the axle

and stator ring; and

circular assembly means for rigidly attaching the inner cylinder to the

stator ring; wherein said inner cylinder, said circular assembly means, said

magnet rotors, said axle means, said circular endplate, and said stator ring

are made at least partially from electrically conductive material.

8. The homopolar machine of claim 7 wherein the rolling means comprises an

electrically conductive geared electromechanical rotary joint.

9. The homopolar machine of claim 7 wherein the rolling means comprises an

electrically conductive copper coating on the stator ring and magnet rotors.

10. The homopolar machine of claim 7 wherein the stator ring comprises

electrically conductive magnetic material.

Related article

Related article